Troubleshooting 18Kw Off Grid Solar Kits Low Voltage Faults

18KW off grid solar kits are a sustainable solar energy solutions commonly used by users. Low-voltage faults that occur during use can interrupt power delivery, causing lights to flicker and electrical appliances to malfunction. First, recognize that low-voltage faults are often caused by a variety of factors, including battery charge status, line resistance, and environmental conditions. Second, realize that active troubleshooting relies on clear measurement practices, such as using a high-quality multimeter to record voltage readings under load. Finally, maintain the optimal performance of your 18kW off grid solar kits through a systematic approach.

Common causes of low voltage faults in 18 kW off grid solar kits

Homeowners often overlook simple problems such as loose connections or terminal corrosion. When checking the DC bus, pay attention to whether there is green or white residue, which indicates oxidation. Additionally, undersized cables may introduce excessive resistance, particularly in long-distance wiring from the solar array to the battery pack. Remember that voltage drop increases with cable length and cable specifications decrease.

Another common cause is the aging of the battery pack. Even sealed AGM or lithium batteries lose capacity over time, causing internal resistance to increase and reducing available voltage under load. In these solar energy solutions for homeowners, regular battery health checks can detect capacity decay before it causes failure. Finally, improperly setting up the inverter or charge controller can also cause the low-voltage cutoff to be triggered prematurely. By reviewing the system manually and adjusting parameters such as the low-voltage disconnect threshold, you can ensure that the equipment operates in harmony with the battery chemistry.

Diagnosing Battery Pack Problems in 18 kW Off-Grid Solar Kits

First, check the voltage of individual cells with a calibrated voltmeter. Unbalanced cells will pull down the voltage of the entire battery pack under load. Next, check the inter-cell connectors for signs of corrosion or loose joints. Even a single bad connection in a series battery pack can create resistance and cause your 18KW off grid solar kits to have Undervoltage errors during peak demand.

For lithium batteries, use the built-in charge status monitor or a USB-connected monitoring tool to verify battery balance. If an imbalance occurs, perform an equalization charge or controlled balance charge to restore uniform voltage levels. Finally, monitor battery temperature: Charging or discharging outside the 32–104°F (1-38°C) range reduces adequate capacity. By diagnosing and correcting these battery bank issues, you can strengthen the core of your sustainable solar solution.

Check Inverter and Charge Controller Performance

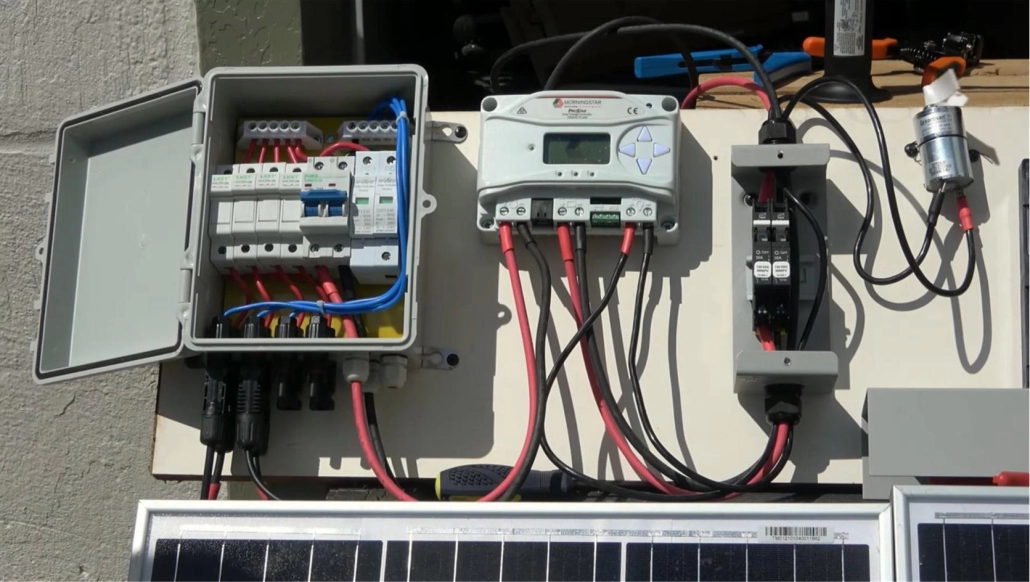

Inverters and charge controllers are key components that regulate the conversion between DC and AC power, as well as the charging of batteries. First, review the error log on the inverter digital display or in a connected monitoring app. Low voltage alarms are often associated with sudden load peaks or inappropriate voltage setpoints. Adjust the low-voltage disconnect threshold within a safe range to prevent premature disconnection while minimizing the risk of deep discharge.

Next, verify the firmware version and update it if necessary. It is also essential to check that the MPPT settings of your charge controller match the specifications of the solar array. Mismatches can also cause undervoltage conditions during sunrise or cloudy days. By carefully checking the performance of the inverter and charge controller, you can ensure that your 18 kW off grid solar kit provides stable and reliable power.

Check the wiring and connections.

The integrity of the wiring determines whether the off grid system operates stably or experiences frequent low-voltage failures. The recommended systematic approach is to mark each cable run and then measure the voltage drop at different load levels. For example, a 2% voltage drop on a 48-volt bus at 100 amps is equivalent to a voltage loss of nearly 1 volt, which is enough to trigger an undervoltage alarm.

Additionally, apply an anti-oxidation compound to exposed copper connections to prevent corrosion, especially in humid environments. Don’t forget the AC wiring. Ensure that the neutral and hot wires share the same conduit, and eliminate ground loops to avoid stray voltages. By effectively checking the cables and connections, you can eradicate low-voltage faults.

Environmental and load factors that affect voltage stability

Environmental conditions and changing load profiles can also put a considerable strain. For example, extreme cold weather increases cable resistance and reduces battery efficiency, causing voltage sags under heavy loads. Conversely, high temperatures accelerate battery aging and can trigger the inverter’s thermal protection, causing the system to shut down temporarily and potentially result in a low-voltage fault. Therefore, we need to install temperature sensors near the battery and inverter and configure a monitoring system.

In addition, unpredictable load patterns may exceed the surge capacity of the inverter. Implement a load-shedding strategy: Prioritize critical circuits, such as cooling and lighting, to ensure your 18 kW off-grid solar kit maintains stable voltage across essential services, creating a more resilient and sustainable solar energy solutions.

Ensure long-term reliability and performance.

Maintaining long-term voltage stability requires a proactive and comprehensive approach to ensure stability. Schedule a quarterly inspection of your entire 18 kW off grid solar kit. Record detailed voltage readings under different load conditions and compare trends over time. And replace components that show signs of wear before they fail under load.